In today’s highly competitive packaging industry, selecting the right polyolefin shrink equipment is critical to production efficiency, product presentation, and total cost of ownership. Whether you’re packaging food, electronics, or consumer goods, the right equipment will support your film choice, line speed, product footprint, and sustainability goals. This guide will walk through the major decision points so you can make an informed polyolefin shrink equipment purchase.

Key Equipment Types and What to Consider

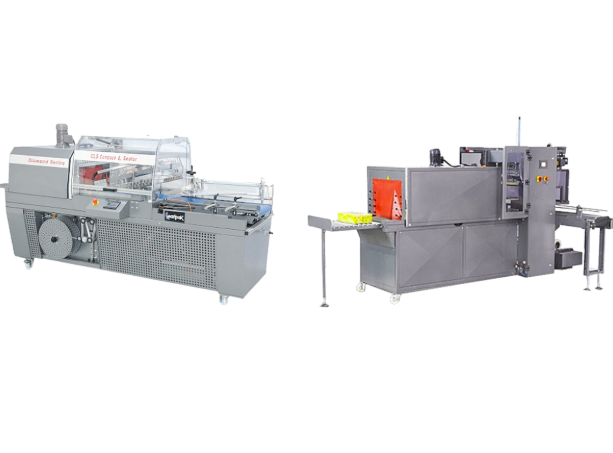

When choosing polyolefin shrink equipment, you’ll typically select between a few common configurations: sealing equipment (e.g., L-bar sealers), shrink tunnels, or combination units that integrate sealing and shrinking. Shrink wrap systems generally wrap your products in films such as polyolefin, polyethylene, or PVC. Here are key features you should evaluate:

Sealing Mechanism and Compatibility

The sealer must be compatible with polyolefin film, which may require different dwell time and temperature settings compared to PVC. Because polyolefin tends to shrink at lower temperatures and has greater elasticity, the sealing element and cutting wire design must support clean, consistent seals without overheating the film.

Shrink Tunnel Design

A shrink tunnel is where the film conforms to the product. Look for adjustable air flow, zoned temperature control, and variable conveyor speeds. Infrared or convection-based tunnels can be chosen depending on the product type. Polyolefin film responds best to even heat distribution, so multi-zone tunnels improve results.

Film Gauge and Roll Size

Different applications call for different film gauges (thickness). A small bakery might use 45–60 gauge for light retail packaging, while heavier industrial goods might require 75–100 gauge. Your shrink equipment should easily handle a range of roll widths and gauges to maintain flexibility for future needs.

Throughput and Line Speed

Consider how many products per minute you need to package. Entry-level L-bar sealers may manage 10–20 packs per minute, while automated side-sealers integrated with high-speed tunnels can exceed 100 packs per minute. Match equipment capacity with current and projected production volume to prevent bottlenecks.

Automation and Integration

Modern polyolefin shrink equipment often comes with programmable logic controllers (PLCs), touchscreen interfaces, and sensors that adjust sealing and tunnel parameters automatically. Integration with existing conveyors, labelers, and printers ensures smooth operation and reduces labor. For growing operations, scalability is a key purchasing factor.

Factors Affecting Equipment Choice

When assessing equipment, go beyond price and evaluate the total cost of ownership. Factors such as film waste, energy consumption, maintenance costs, and operator training can influence long-term savings. Also consider available space in your facility, as shrink tunnels and combination systems require proper ventilation and clearance.

Product Variety and Shape

Polyolefin shrink film works well with a wide variety of product shapes — from boxes to irregular or multi-packed items. Equipment with adjustable film folders, sealing bars, and guides will accommodate diverse product sizes, reducing downtime for changeovers.

Sustainability and Efficiency

Polyolefin is recyclable and generally more environmentally friendly than PVC. Investing in energy-efficient shrink tunnels, auto-sleep modes, and reduced film waste systems contributes to sustainability goals and operational efficiency.

Testing and Supplier Support

Before purchasing, request a film and product test from your supplier. A reputable equipment manufacturer will evaluate your product samples, recommend proper film types, and fine-tune machine settings to achieve optimal shrink appearance and speed. After-sales support, spare parts availability, and training programs are also crucial for smooth operation.

Conclusion

Selecting the right polyolefin shrink equipment requires balancing film compatibility, throughput, automation, and sustainability goals. As packaging operations evolve toward higher automation and sustainability, the right investment in polyolefin shrink systems ensures your business remains competitive within the broader field of packaging machinery. By understanding how the film behaves and what equipment configurations best fit your packaging environment, you can improve product presentation and efficiency while reducing waste.