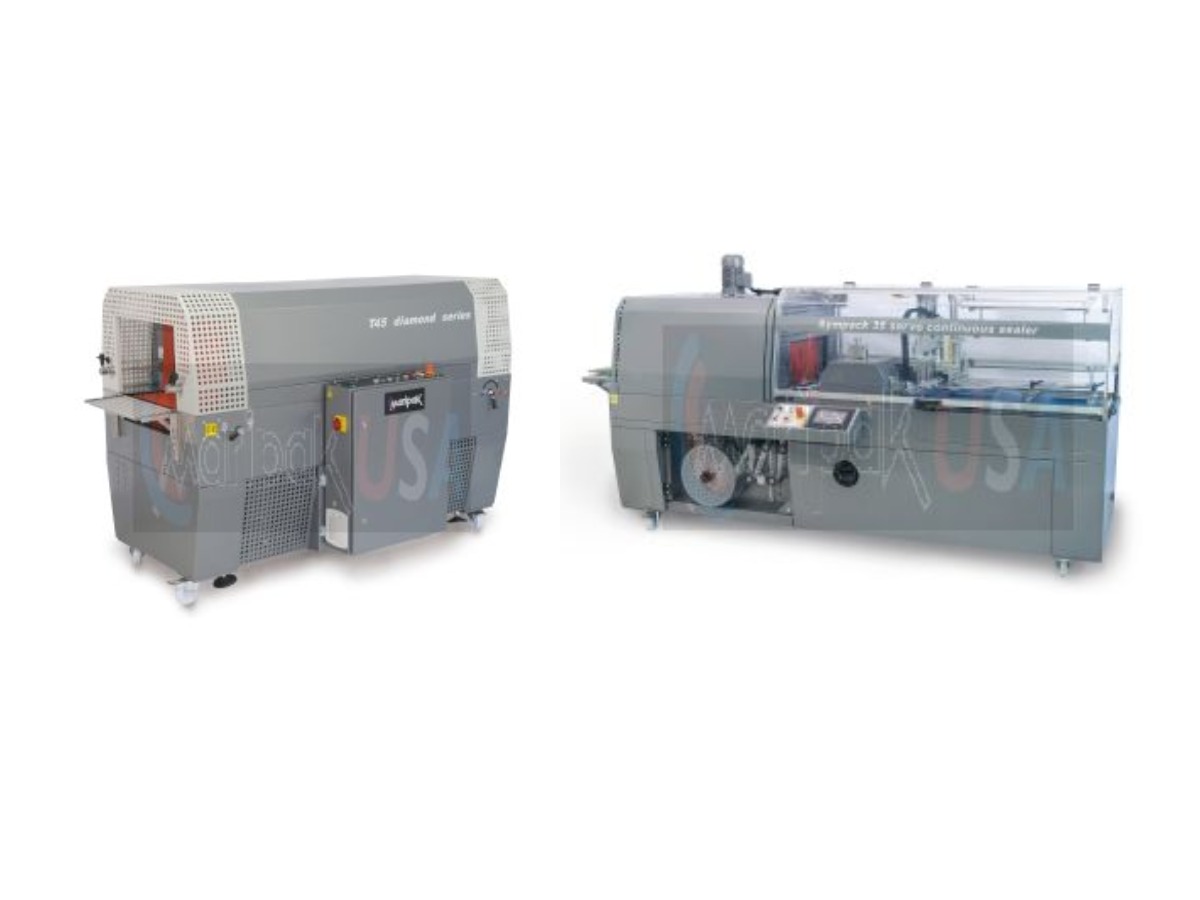

Efficient packaging is essential for product protection and presentation, which makes the proper use of a shrink film machine critical for many businesses. While these machines simplify the wrapping process and enhance product safety, incorrect operation can lead to wasted materials, production delays, and equipment damage. Understanding the most common mistakes and how to avoid them ensures that businesses maximize the benefits of their shrink film machine. Brands like Maripak offer reliable machines, but proper usage is key to maintaining efficiency and product quality.

Using the Wrong Type of Shrink Film

One of the most frequent errors is using incompatible shrink film with the machine. Different shrink film machines are designed for specific types of films, including polyolefin, PVC, or polyethylene. Using the wrong film can lead to uneven shrinking, tearing, or incomplete sealing. Businesses should always match the film type and thickness with the machine’s specifications to ensure smooth operation and professional results.

Improper Heat Settings

Temperature control is critical when operating a shrink film machine. Too high a temperature can cause the film to over-shrink, burn, or create wrinkles, while too low a temperature may result in loose packaging that doesn’t protect the product appropriately. Operators must carefully follow the manufacturer’s guidelines and adjust heat settings based on the film type, package size, and ambient conditions. Regular calibration ensures consistent results. Additionally, monitoring the machine during operation can help detect any uneven heating or hot spots, allowing for immediate adjustments. Using a digital thermometer or built-in temperature sensors can further improve accuracy and prevent costly mistakes.

Neglecting Routine Maintenance

Another common mistake is neglecting routine maintenance. Shrink film machines involve moving parts, heating elements, and rollers that require regular inspection and cleaning. Failure to maintain these components can lead to mechanical failures, decreased efficiency, and higher repair costs. Cleaning the machine, checking belts, and lubricating moving parts at scheduled intervals prolongs the machine’s lifespan and ensures smooth operation.

Overloading or Misaligning Products

Overloading the machine or misaligning products on the conveyor can cause jams, inconsistent wrapping, and damaged packaging. Ensuring proper spacing and alignment allows the shrink film machine to apply uniform heat and pressure. Training staff to load products correctly reduces errors, prevents downtime, and maintains a professional appearance for packaged goods.

Ignoring Safety Protocols

Safety is paramount when operating a shrink film machine. Operators often make the mistake of bypassing safety mechanisms or not wearing protective gear. Exposure to heated elements, moving parts, or sharp blades can result in injuries. Businesses must enforce strict safety protocols, including proper training, protective gloves, and clear instructions for machine operation.

Inadequate Training of Operators

Even the most advanced shrink film machines require knowledgeable operators. Lack of proper training leads to inconsistent results, material waste, and potential equipment damage. Providing comprehensive training ensures that staff understand heat adjustments, loading techniques, and troubleshooting procedures. Well-trained operators enhance productivity and reduce unnecessary costs.

Failure to Monitor Film Tension

Incorrect film tension is another common issue. A film that is too tight can cause tearing, while one that is too loose leads to poorly wrapped products. Monitoring and adjusting tension settings regularly ensures that the shrink film machine performs optimally, delivering professional, secure packaging every time.

Conclusion

Avoiding these common mistakes allows businesses to maximize efficiency, reduce waste, and maintain high-quality packaging with their shrink film machine. Choosing a reliable brand like Maripak provides a strong foundation, but consistent attention to film type, heat settings, maintenance, and operator training is essential. For businesses seeking automated solutions that further streamline the packaging process, investing in an auto shrink wrap machine can enhance productivity, reduce errors, and maintain consistent results across large-scale operations.