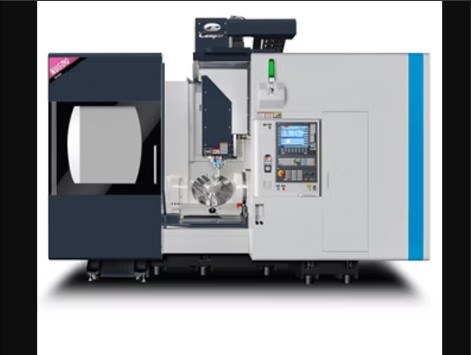

Precision manufacturing plays a critical role in industries where safety, accuracy, and consistency are non-negotiable. Aerospace and medical manufacturing demand extremely tight tolerances, complex geometries, and repeatable quality across every component produced. In the middle of advancing high-precision production methods, a 5-axis vertical machining center has become an essential solution for manufacturers seeking efficiency without compromising accuracy. Its ability to machine complex parts in a single setup makes it especially valuable in these highly regulated sectors.

Why Precision Matters In Aerospace And Medical Manufacturing?

Both aerospace and medical industries operate under strict standards and compliance requirements.

Aerospace components must withstand extreme temperatures, pressure, and mechanical stress, while medical parts often interact directly with the human body. Even minor deviations can lead to serious performance or safety issues. The 5-axis vertical machining center allows manufacturers to achieve micron-level precision while maintaining consistency across high-volume or custom production runs.

By reducing manual repositioning and setup changes, manufacturers minimize the risk of dimensional errors and surface defects.

Complex Geometry Made Possible With 5-Axis Machining

One of the biggest advantages of advanced machining lies in its ability to handle intricate shapes.

A 5-axis vertical machining center enables simultaneous movement across multiple axes, allowing tools to approach the workpiece from nearly any angle. This capability is essential for aerospace components such as turbine blades, engine housings, and structural brackets that feature curved surfaces, undercuts, and compound angles.

In medical manufacturing, this same capability supports the production of implants, prosthetics, and surgical tools that require smooth contours and exact anatomical accuracy.

Reduced Setup Time And Increased Efficiency

Efficiency is critical in industries where production delays can be costly.

Traditional machining methods often require multiple setups, fixtures, and machine transfers to complete a single part. With a 5-axis vertical machining center, complex components can often be machined in one setup. This significantly reduces lead times, lowers labor costs, and improves workflow efficiency.

Fewer setups also mean less handling of the workpiece, which helps maintain dimensional accuracy and surface integrity—both essential in aerospace and medical applications.

Aerospace Applications Of 5-Axis Vertical Machining

Aerospace manufacturing benefits greatly from advanced machining capabilities.

Aircraft components frequently require lightweight materials such as aluminum, titanium, and high-performance alloys. A 5-axis vertical machining center allows manufacturers to machine these materials efficiently while maintaining structural integrity.

Common aerospace applications include:

- Turbine blades and impellers

- Engine mounts and housings

- Structural airframe components

- Complex brackets and fittings

The ability to maintain tight tolerances across complex geometries supports both performance and safety requirements.

Medical Industry Use Cases And Advantages

The medical sector relies on precision and repeatability more than almost any other industry.

A 5-axis vertical machining center is widely used to manufacture orthopedic implants, dental components, surgical instruments, and custom prosthetics. These parts often require smooth finishes, intricate shapes, and exact dimensions to ensure patient safety and comfort.

Because many medical components are produced in small batches or customized per patient, the flexibility of 5-axis machining allows manufacturers to adapt quickly without sacrificing quality.

Improved Surface Finish And Tool Access

Surface quality is critical in both aerospace and medical manufacturing.

A 5-axis vertical machining center improves surface finish by maintaining optimal tool orientation throughout the machining process. This reduces tool marks, vibration, and secondary finishing operations.

In medical components, smoother surfaces reduce the risk of bacterial growth and improve biocompatibility. In aerospace parts, a better surface finish contributes to improved aerodynamic performance and reduced wear.

Conclusion

Aerospace and medical manufacturers rely on advanced machining solutions to meet demanding standards for accuracy, safety, and efficiency. By enabling complex geometries, reducing setup time, and improving surface quality, a 5-axis vertical machining center plays a critical role in producing high-performance components for both industries. In the middle of modern precision manufacturing strategies, these systems complement broader production capabilities offered by vertical machining centers, helping manufacturers maintain quality, scalability, and compliance in highly regulated environments.